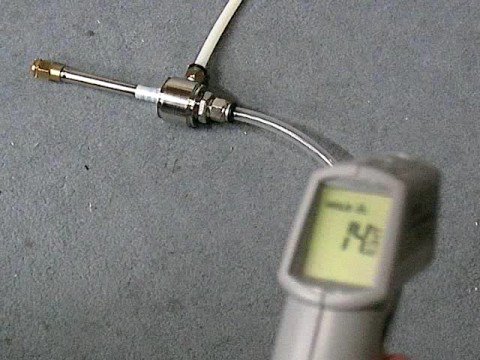

Vortex tubes have one inlet and two outlets. Compressed air (or gas) is put into inlet under pressire, where it is spun at high speed due to the design of the chamber. The high rate of spin which is often over a million rpm, causes the air to split into two streams, with one stream giving kinetic energy to the other. The result is two outlets, one with hot air and the other with cold.

Vortex tubes have no moving parts, are almost maintenance free and tend to be very reliable. However they have lower efficiency compared to most other heat pumps.

The cold air can be adjusted down to -40 degrees Centigrade, and the hot side can be adjusted up to a temperature of 120 degrees Centigrade. The vortex tubes have an adjustable valve at the "hot" end controls the volume of the air flow, and the temperature exiting at the cold end. By adjusting the valve, you control the "cold fraction" which is the percentage of total input compressed air the exits the cold end of the vortex tube.

Vortex tubes also known as Ranque-Hilsch vortex tubes or Wirbelröhre

In Summary they are:

- Powered by compressed air

- Exceptionally reliable, no moving parts to break or wear

- Low-maintenance

- Less efficient than many refrigerant-based systems

This particular vortex tube is ideal for use with smaller compressors as it does not require a large volume of air. Its preferable if an oil and water free air supply is used (keeps vortex tube clean). Typically a 1.5hp or 2hp compressor will be able to run this vortex tube.

| Specifications | |

| Model no: | 3204 |

| Volume of air: | 4 SCFM (113 SLPM) |

| Pressure (for best results): | 80 to 100 PSIG (5.5 - 6.9 BAR) |

| Inlet: | 1/4 NSP + 10mm push fit adapter |

| Outlet: | 3/8 NSP + 12mm push fit adapter |